Gps antenna fabrication (GPS antenna fabrication, from basic to proficient)

With the wide application of global positioning system (GPS) technology, GPS antenna plays an important role in various fields. GPS antenna is the key equipment for receiving GPS satellite signals, and its performance directly affects the positioning accuracy and reliability. It is of great practical significance to study and discuss the manufacture of GPS antenna. This paper will introduce the basic knowledge, steps and matters needing attention in the manufacture of GPS antenna. Help readers to master GPS antenna production technology from basic to proficient.

Basic knowledge of GPS Antenna making

1. Antenna principle: GPS antenna works based on the principle of electromagnetic wave, and realizes positioning by receiving radio signals transmitted by GPS satellite. Understanding the principle of electromagnetic wave propagation and the basic structure of antenna is the basis of making GPS antenna.

2. Material selection: the materials involved in the manufacture of GPS antenna include antenna substrate, RF connector, coaxial cable, shell and so on. The selection of appropriate materials is very important to improve the performance and stability of the antenna.

3. Design and simulation: when designing the GPS antenna, we need to consider the antenna size, shape, frequency response, polarization mode and other factors. Using modern electromagnetic simulation software, the performance of the antenna can be predicted and optimized in the design stage.

Manufacturing steps of GPS antenna

1. Preparation: according to the design requirements, prepare corresponding materials, tools and equipment, common tools include engraving knife, electric iron, multimeter, etc., equipment including vector network analyzer, signal generator and so on.

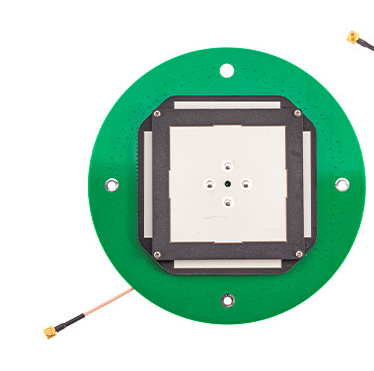

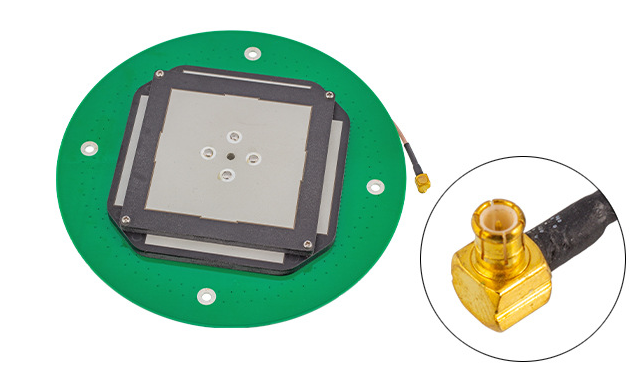

2. Make the substrate: according to the design, make the antenna substrate, the substrate material can choose PCB board, aluminum substrate and so on. The manufacturing process includes drawing, engraving, copper coating and other steps.

3. Welding components: welding RF connectors, coaxial cables and other components to the corresponding position of the substrate, the welding quality should be paid attention to in the welding process to ensure reliable connection.

4. Assemble and debug: assemble the welded components, complete the appearance of the antenna, debug the antenna and check whether its performance meets the design requirements.

5. Testing and optimization: the antenna is tested by using test equipment such as vector network analyzer. According to the test results, the antenna is optimized to improve its performance.

Matters needing attention in making GPS Antenna

1. Precision control: in the manufacturing process, it is necessary to strictly control the dimensional accuracy and welding quality to ensure the stable and reliable performance of the antenna.

2. consideration of material selection: when selecting materials, the performance, cost and availability of materials should be fully considered in order to produce cost-effective products.

3. Environmental factors: consider the influence of the environment of the antenna on the performance, such as temperature, humidity, wind load, etc., in order to ensure the performance stability of the antenna in various environments.

4. Safe operation: in the production process, attention should be paid to safe operation to avoid burns, electric shocks and other accidents.

5. Continuous optimization: in the process of manufacturing, the experience is constantly summarized, and the antenna is optimized according to the test results to improve its performance.

Case analysis

Take a GPS module antenna as an example, its fabrication process includes design, material selection, fabrication of substrate, welding components, assembly, debugging and test optimization. In the design stage, electromagnetic simulation software is used to simulate and optimize the size, shape and frequency response of the antenna. In the material selection stage, considering the cost, performance and availability and other factors, the appropriate material is selected. Strict control of dimensional accuracy and welding quality, through testing and optimization, to achieve a high-performance GPS module antenna.

The fabrication of GPS antenna is a comprehensive technology, which needs to master the knowledge of antenna principle, material selection, design and simulation, manufacturing steps and matters needing attention. Through continuous study and practice, we can master the manufacturing technology of GPS antenna from foundation to proficiency. This paper hopes to provide the basic knowledge and methods of GPS antenna production for beginners and provide reference for further improving the production level of GPS antenna.